application:

the equipment is batch type induction furnace, mainly used in tungsten carbide, silicon carbide, boron carbide, polysilicon material, calcium carbide, sapphire, rare earth oxide, metal, billets, powder metallurgy, vanadium carbide powder and such as metal powder and composite metal powder.

configuration:

380v±10%,50hz/60hz 3 phase 5 wire

one control cabinet to one furnace and optional for one to two type or one to four type.

|

model parameter |

lab usage |

production usage |

|||||

|

nti-sjl-54w |

nti-sjl-98w |

nti-sjl-300w |

nti-sjl-484w |

nti-sjl-1280w |

nti-sjl-1620w |

||

|

working size |

mm |

300×300×600 |

350×350×800 |

500×500×1200 |

550×550×1600 |

800×800×2000 |

900×900×2000 |

|

heating type |

/ |

if induction heating |

|||||

|

control type |

/ |

thyristor control or igbt control ( optional ) |

|||||

|

ht zone capacity |

l |

54 |

98 |

300 |

484 |

1280 |

1620 |

|

loading weight |

g |

ht zone capacity × density (g/cm³)×1000 remark:1l=1000cm³ |

|||||

|

ultimate vacuum |

pa |

20 |

|||||

|

if power |

kw |

120 |

160 |

200 |

250 |

400 |

600 |

|

max. working temperature |

℃ |

2500 |

2500 |

2500 |

2500 |

2500 |

2500 |

|

usual working temperature |

℃ |

2400 |

2400 |

2400 |

2400 |

2400 |

2400 |

|

temperature unifomity |

℃ |

±10 |

±10 |

±10 |

±10 |

±10 |

±10 |

|

working environment |

/ |

vacuum or ar, n2 atmosphere protection( micro positive pressure) |

|||||

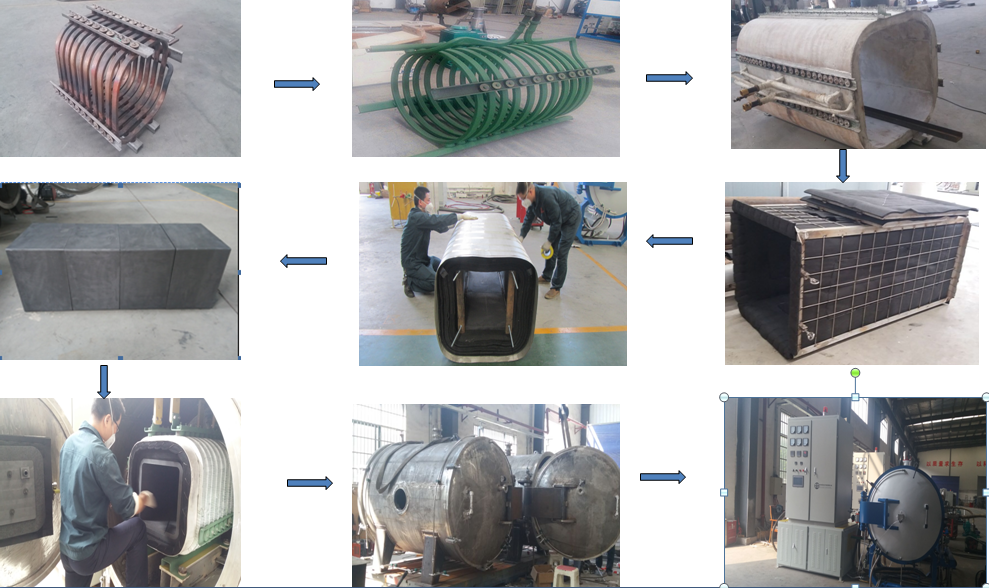

feature:

1.furnace door:rotary hinge; manual / automatic lock tight

2.furnace shell:all carbon steel/stainless steel inner/all stainless steel

3.furnace inner liner :soft carbon felt and hard composite felt / full hard composite felt

4. heater material: static pressure graphite / three-high graphite molding

5.furnace body:vertical type/ horizontal type

6.gas circuit control:volume/mass flow-meter;manual value/automatic value;import/domestic

7.vacuum pumps and vacuum gauges: import / domestic

8. skip: raceway / forklift

9.operation panel:analog screen / touch screen / industrial control machine

10.plc:delta / omron / siemens / mitsubishi

11.temperature control instrument: shimaden /oulu

12. temperature measuring type: infrared optics temperature measuring instrument/ c index number thermocouple (wolfram / mo / ceramic bushing)

13. recorder: paperless recorder / paper recorder; import / domestic

14. electrical element: chint / schneider / siemens /abb