15.much easier and more convenient operation which names automatically furnace door open through touch screen operated.

horizontal type:

|

model parameter |

lab usage |

production usage |

|||||

|

nti-sjl-54w |

nti-sjl-98w |

nti-sjl-300w |

nti-sjl-400w |

nti-sjl-1280w |

nti-sjl-1620w |

||

|

working size |

mm |

300×300×600 |

350×350×800 |

500×500×1200 |

500×500×1600 |

800×800×2000 |

900×900×2000 |

|

heating type |

/ |

if induction heating |

|||||

|

crucible |

/ |

graphite |

|||||

|

control type |

/ |

thyristor control or igbt control ( optional ) |

|||||

|

ht zone capacity |

l |

54 |

98 |

300 |

400 |

1280 |

1620 |

|

loading weight |

g |

ht zone capacity × density (g/cm³)×1000 remark:1l=1000cm³ |

|||||

|

ultimate vacuum |

pa |

20 |

|||||

|

if power |

kw |

120 |

160 |

200 |

250 |

400 |

600 |

|

max. working temperature |

℃ |

2500 |

2500 |

2500 |

2500 |

2500 |

2500 |

|

usual working temperature |

℃ |

2400 |

2400 |

2400 |

2400 |

2400 |

2400 |

|

temperature unifomity |

℃ |

±10 |

±10 |

±10 |

±10 |

±10 |

±10 |

|

overall dimension |

mm |

|

|

|

|

|

|

|

weight |

kg |

|

|

|

|

|

|

|

working environment |

/ |

vacuum or argon atmosphere protection( micro positive pressure) |

|||||

you can customize it as per your real requirement.

380v±10%,50hz/60hz 3 phase 5 wire

one control cabinet to one furnace and optional for one to two type or one to four type.

1.adopting special furnace inner liner structure and heater arrangement, it has good uniformity of the furnace temperature.

2.adopting special structure for the degreasing chamber, efficiency sealing, completely degreasing and no pollution to the inner element.

3. vacuum sintering furnace has flexible vacuum pumping, vacuum sintering, micro positive pressure sintering, partial pressure sintering, micro positive degreasing, and other functions;

4. adopting the most advanced heat insulation structure and materials, good heat insulation performance of furnace liner, less heat, more than traditional design energy saving 25%.

5.adopting touch screen operation, plc centralized control, simple operation, high reliability.

6. vacuum sintering furnace has the alarm function of ultra-temperature and ultra-voltage, mechanical and automatic for pressure protection action, interlocking functions, high safety equipment.

7.vacuum sintering furnace has remote operation、remote fault diagnosis and remote software upgrades and other function.

8. the hard alloy products sintered by our vacuum sintering furnace can reach to 58hrc of hardness.

9. much easier and more convenient operation which names automatically furnace door open through touch screen operated

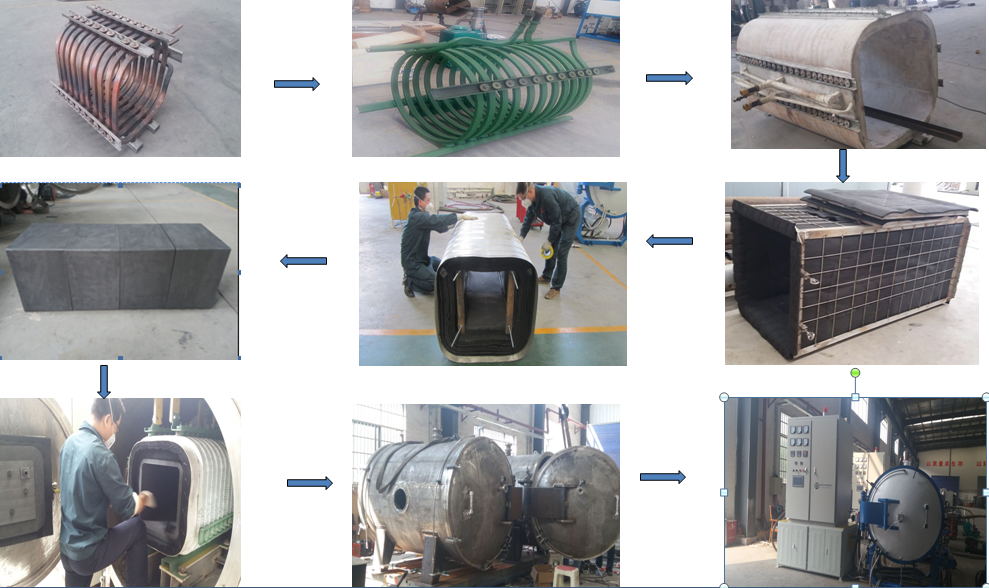

![[s]160.jpg](/uploads/image/ackai/20230509/20230509135743_1205.jpg)

![[s]156.jpg](/uploads/image/ackai/20230509/20230509135749_3999.jpg)

![[s]161.jpg](/uploads/image/ackai/20230509/20230509135755_2437.jpg)