|

model parameter |

lab usage |

production usage |

|||||

|

nti-thl-54w |

nti-thl-243w |

nti-thl-300w |

nti-thl-400w |

nti-thl-720w |

nti-thl-720 nw |

||

|

working size |

mm |

300×300×600 |

450×450×1200 |

500×500×1200 |

500×500×1600 |

600×600×2000 |

(600-800)×(600-800)×(2000-4000) |

|

control process |

|

thyristor control |

|||||

|

heating type |

/ |

resistance heating |

|||||

|

ht zone capacity |

l |

54 |

243 |

300 |

400 |

720 |

720 n |

|

loading weight |

g |

ht zone capacity × density (g/cm³)×1000 remark:1l=1000cm³ |

|||||

|

ultimate vacuum |

pa |

20 |

|||||

|

if power |

kw |

50 |

105 |

120 |

135 |

189 |

189-500 |

|

heating zone |

zone |

1 |

3 |

3 |

3 |

3 |

3-6 |

|

max. working temperature |

℃ |

1600 |

1600 |

1600 |

1600 |

1600 |

1600 |

|

usual working temperature |

℃ |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

temperature unifomity |

℃ |

±5 |

±5 |

±5 |

±5 |

±5 |

±10 |

|

working environment |

/ |

vacuum or ar, n2 atmosphere protection( micro positive pressure) |

|

||||

|

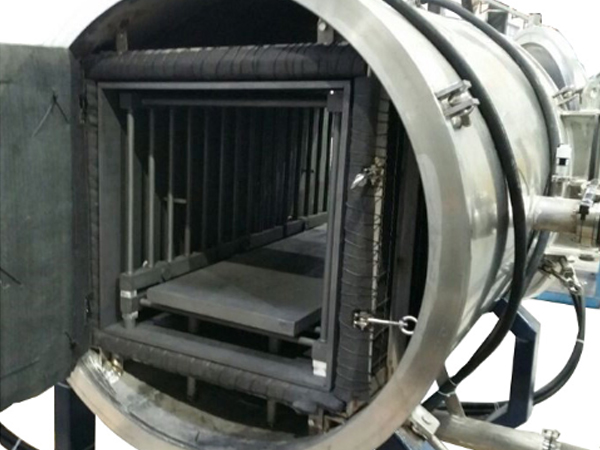

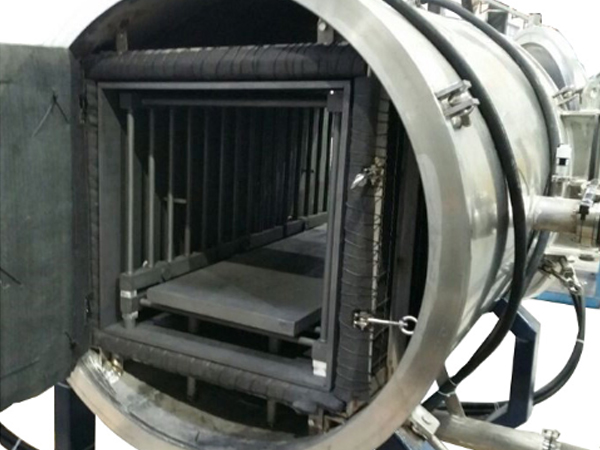

model |

nti-thl-400w |

|

max.temperature |

1600℃ |

|

working tem. |

1500℃ |

|

input voltage |

380v±10%,50hz/60hz |

|

rated power |

135 kw |

|

heating area |

3 regions |

|

ht area size |

540 mm × 540 mm × 1600 mm |

|

effective heating |

constant tem.area: 500 mm × 500 mm × 1600 mm |

|

tem.measurement |

tungsten rhenium thermocouple(0℃--1700℃) |

|

tem.controlling |

shimadne automatic control and high precision adjustable manual control.(accuracy:0.3) |

|

exhaust way |

smart or manual for choice. |

|

accuracy |

±0.25% tips:up to infrared probe accuracy grade |

|

tem.uniformity |

≤±5℃。(after 30min of heating ) |

|

inner atmospher |

vacuum or ar、n2 atmospher(micro-positive pressure) |

|

alarm system |

plc smart pre-alarm、alarm and power supply protection |

|

filtration |

4 grades purifing system |

|

cooling |

closed inner circulating water cooling/ fbp-2a |

|

purifing |

argon gas purifier /gya-4c |

|

ipc |

mcgs (tpc1061ti),(delta)plc |

|

vacuum system |

side valve type vacuum pumph-150( 1set)、vacuum valve、pipeline and vacuum gauge vacuum degree:20pa

|

|

total weight |

about 5 tons |